An Introduction To Gear Box Manufacturing

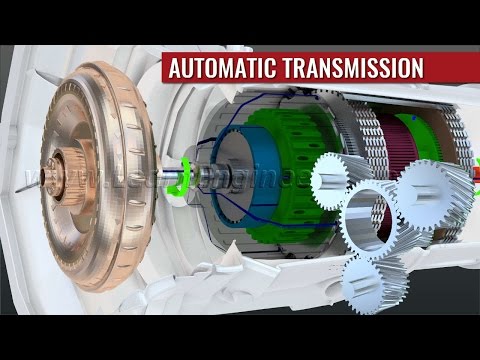

The gearbox is among The most crucial portions of an automatic electric powered gun. This is taken into account the center of the AEG for whether it is damaged or not appropriately preserved; the gun will never accomplish as expected or even worse, will ruin your entire mechbox or system box. For these good reasons, it is significant to understand the performance from the gearbox as well as its elements and maintenance.

A typical rifle like an Airsoft M16 has 3 gears. The Bevel, Spur and Sector gears.

The Bevel Equipment is the a person linked to the motor. It can be slightly conical in condition to become perpendicular for the motor. It's got Yet another list of more compact enamel that is then linked to the Spur Gear.

The Spur Equipment is definitely the one that augments the spinning electricity of the motor from the Bevel for the Sector Gear. The scaled-down list of enamel in the Spur gear gives a considerably faster spin for the Sector gear.

The Sector Equipment also has two sets of enamel. One particular set is linked to the lesser tooth in the Spur Equipment. The opposite one particular doesn't have a complete set of teeth to surround the equipment. This Component of the gear functions given that the capture and release on the piston. It catches the piston and pulls it back again compressing the spring behind the piston. And since the equipment does not have a complete set of enamel the piston gets released and pushes the air to a small hole where a BB is positioned.

These gears get the job done in unison with The complete mechbox. It starts off in the cause because it connects the move of ability in the battery for the motor (in the majority of electric powered Airsoft guns ). The motor then turns the Bevel Gear which turns the Spur Equipment from its outer set of the tooth. The more compact set of enamel of the Spur Equipment rotates speedier and therefore turns Sector Equipment considerably quicker. The Sector Gear then does its job of pulling again the piston to compress the spring behind it. The piston, when launched, then compresses the air in the Place in front of it by way of a small opening pushing a BB pellet out in the barrel at a specific pace. This process is recurring in a considerably faster amount.

To keep this gears Operating adequately, they should generally be cleaned of Grime. Soon after cleaning it ought to be lubricated to lessen friction and reduce the possibility of heating up. It is usually recommended to prevent firing and give someday https://www.diskedge.com/manufacturing/ for the gears to cool down if it overheats. Gears that are comprised of plastic tend to melt with extended use when those made out of metallic are inclined to warmth up speedier but gives a lot more power.

Nonetheless, it's best to go with the metallic geared gearbox because it will final for a longer time and is not going to stop working as quick as the generic plastic gears. Most Airsoft guns comes along with plastic gearbox assembly but the higher high quality designed Airsoft guns much like the Airsoft sniper rifles http://topairsoftsniperrifles.com are equipped with metal gears. Usually do your investigation before you decide to come to a decision to select a gun.

7 Simple Secrets To Totally Rocking Your How To Gear Manufacturing

Just before picking a gear motor for your operation, it's important to grasp what a gear motor is, what it does and any specialized and mechanical constraints that exist above other motor varieties You can utilize.

Equipment motors is often referred to as a complete motion drive system that consist of a electrical motor and reduction gears that happen to be typically built in just a one casing. Within just this casing each the motor as well as the gears is usually configured for exact engineering.

Additionally, housing with the gears and motor in the same style casing signifies that it can be much easier to lessen the dimensions of your components above selecting a separated motor and gear rack. Therefore, you might frequently uncover most of these motors within just ability applications and electrically driven machines which can be dependent on measurement and bodyweight restrictions. These motors can on the other hand be upsized to electrical power professional lifts or downsized to energy alarm clocks for the house.

One of the major benefits of a equipment motor is that they are suitable for output speed reduction although the torque is enhanced. Even so This is often proportionate in ratio.

This kind of speed reduction gearing allows lesser electrical motors to mobilise bigger masses, even though it has to be mentioned this tends to be slower than an alternate larger electric motor.

The reduction gears are created up of smaller sized gears that consequently generate larger gears. Typically There are a variety of gears sets to control the ability and torque outputs. These motors are not just utilized to improve electric power and torque, but tend to be utilised to lessen electrical power. A great example is within a small alarm clock. A small electric motors employed in the clock would require different sized gears to power the hour hand, moment hand and second hand. The gears will probably be tuned based on the motor delivering the right standard of rpm although taking into consideration any elements of friction which have occur because of the electric motor clock system. This exact same principle is applied in much larger applications of gear motor products.

Torque management is an additional configurable advantage of applying https://www.storeboard.com/blogs/general/undeniable-proof-that-you-need-how-to-gear-manufacturing/2169418 gear motors in excess of other types of electric motor. Torque reduction is necessary when a big load or power is needed for being slowed down. An illustration of This is able to be for hospital hoists used to transfer large or immobile sufferers from mattress to bed and reclining furnishings the place the load or weight staying lifted or reclined is not likely to be the exact same.

Many gear motors manufactured now for industrial apps are AC-powered. Also they are mounted pace gears, nevertheless you'll find variable speed gear motors that can provide a higher diploma of configuration and ability/torque Management. Alternatively there are actually DC gear motors which can be frequently used on car or truck and relocating apps which include windscreen wipers and breakdown Restoration electrical power winches and pulleys.

These kinds of motors are ever increasing in utilization from manufactures who provide products each for sector and in fact inside of our dwelling. From electric can openers to washing devices, electric equipment motors are A part of daily life around the world.

The Biggest Trends In Get Gears Manufactured We've Seen This Year

Industrial Gears are mainly toothed formed machinery element like wheel or cylinder. Gear is a part that rotates by applying drive into the tooth of another device to create mechanical advantage. They are mechanical devices to transmit movement or change the pace. Different mechanical pros involves auto transmission of motor or every other automobiles. Motor vehicle engines and transmissions has gears which drives the engine to maneuver into motion or pace. Other example of items owning gears are pendulum clocks and Hand Mixer or Mixer Grinder etcetera. Gears also adjusts the route of rotation, gears are created in this type of way to enhance or lessen power or pace.

The meshing of gears to a different gear tooth suggests the circumferences moves at a similar price with the the motion or force. Because rotational pace is proportional to your wheel's circumferential pace divided by its radius, thus the more substantial the radius of a equipment, the slower will be its rotational pace, when meshed using a gear of supplied measurement and pace. In almost any engine or motor gears are established As outlined by its velocity.

Industrial gears are of assorted forms for example spur gears, helical gears, double helical gears, bevel gears, worm gears, pinion gears, spiral bevel gears and so on. A number of them are mentioned beneath:

* Spur gears: These gears are the most typical equipment which relatively looks like cylinder or disk. The tooth of these gears are set in such a way so that it is aligned parallel to your axis in the rotation. These gears should to generally be fitted to parallel axles, only then it rotates jointly effectively.

* Helical gears: Helical gears are opposite to spur gears plus much more refined. These gears are set at an angle instead of parallel into the axis of rotation. Helical gears operates more effortlessly and

* Double helical gears: Double helical gears are of considerably more advantageous than helical gears, What's more, it provides precisely the same smoothness as helical gears but coupled with additional worth of increased power during the motion of its enamel as well as it does not give side strategies power.

* Bevel gears: Bevel Gears are majorly used for the shafts from the main shaft to your back again shaft. These are typically equipped in the rear axle of motorcars in addition to Utilized in the push of numerous http://troyfsuy051.zoninrewards.com/gear-manufacturing-explained-in-instagram-photos device resources.

* Worm equipment: These gears are fundamentally utilized for wheel equipment in any motor autos. It can be way of driving two shafts collectively which provides way more effectiveness than almost every other gears. They are either one or multi-get started threaded.

Industrial gears are handy for many applications in the numerous industries. A number of them are mentioned below:

* Cement Plants Market

* Petrochemical Field

* Sugar Mills

* Power Sector

* Mining Sector

* Metal Rolling Mills

* Oil refineries

* Sugar Mill Drives

Industrial gears are of terrific mechanical benefits, these pros are as follows:

* Higher loading potential.

* Larger effectiveness and trustworthiness.

* Value success

* Economical Good quality

* Servicing optimizing the effectiveness of your gears.

25 Surprising Facts About What Is Gear Manufacturer

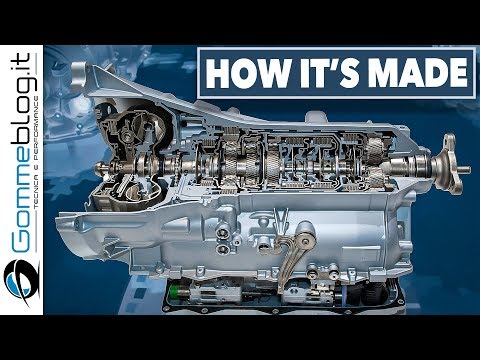

Gears are the main Component of the motor of any motor, vehicle or any device. It ought to be includes good quality to exist In the end. Currently there are plenty of gear companies in the world. However the issue is how it may be regarded as which just one is the greatest. The manufacturing corporation which manufactures many of the areas of a gear box or all kinds of good quality, is unquestionably the most effective 1. There is a wide range variety of equipment containers. These are generally Industrial Gears, Vehicle Gears, Shaft Mounted Gearbox, Helical Gearbox, Planetary Gearbox, Equipment Couplings, Worm Reduction Gearbox and Geared Motors.

Every kind of industrial gears fulfill the economic criteria. Applying the best quality of raw product tends to make these solid and steady. Industrial Gears requires in Interior, Helical, Spur and Profile Ground, Flywheel Ring, Sprockets, Spiral Bevel, Axle Shafts and Worm Wheel. The Car Gears include a variety of components like Spur, Bevel, Helical, Spiral Bevel, Axle Shafts, Gears, Mitre Gears, Flywheel Ring Gears, Timing Gears, Annulus Carriers, Spline Shafts, Chain Sprockets, Pet dog Clutches, Carrier Assemblies and Couplings. The most beneficial gear makers make these all elements of industrial with many endeavours.

The spur gears aid in friction reduction. They're incredibly successful and make out there a secure velocity motion with constant electric power. Profile ground must have these high-quality that may go Using the Worldwide specifications. They're made-up https://www.liveinternet.ru/users/degilcabo4/post468161407// by using the quality course of Uncooked materials which materials outstanding power, toughness and absolute trustworthiness in products and services. The helical lower pollution, sounds and provide easy action. Bevel are enormously valuable in the event the observe of the shaft's rotation is needed being adjusted. These are definitely obtainable with various shaped enamel. These are identified for his or her toughness and combating ability for have on and tear. Every single and each modest Portion of gear box Participate in a significant part in operation or in push. Consequently many of the parts for this producing needs to be in good fashion and needs to have The good high-quality as described it Beforehand. So, this should be the main aim of all great equipment suppliers.

Gears are the base of any engine or any machine in the world. The friction created among the ensure it is noisy. Whether it is properly made up with good quality of Uncooked substance then there is nothing to worry. If they are not created thoroughly or if these include Substantially attract back then there absolutely might be an incredible trouble. So you have to stumble upon the most effective equipment companies to avoid all types of troubles related to equipment boxes.

5 Killer Quora Answers On How To Gear Manufacturing

Equipment Bins are regarded as the central ingredient of any transmission procedure. This box typically presents correct equipment reduction. This really is employed for changing the pace of engine into torque which propels the motor ahead. These types of boxes are useful for enhancing torque and in precisely the same time it lowers the speed of driveshaft. It is viewed which the driveshaft of the gear box rotates gradually as opposed to velocity in the driveshaft of the motor. This difference in the speed creates thrust and boost the torque.

Kinds of Gear Bins

Guide transmission and computerized equipment containers are commonly out there in different https://www.diskedge.com/quality/ shapes and sizes. Guide varieties are The only sort of this box and usually entail handbook movement of the variety of sliding gear. These are generally moved with the assistance of shifter which happen to be attached with this particular box. An automated box is comparable to those guide boxes and only exception would be that the transmission devices automatically find the correct gear. This type of equipment system generally lessens the need of the operator. In these automated equipment containers a suitable hydraulic system is employed for detecting the strain of any fluid present from the engine. This allows the system to pick out good equipment. These computerized techniques use a converter which converts the torque.

There are actually vary sort of packing containers which happen to be Utilized in numerous industries like paper, aerospace, mining, pulp and agriculture. Worm, spur, helical and floor boxes are employed for a variety of industrial needs. Hardened and floor containers are considered as the top form of equipment boxes are regarded as the best variety of packing containers that may be made use of in numerous industries.

Products made use of

The majority of these ground bins are made out of resources like chrome steel, nickel and titanium. Forged iron, bronze and steel is useful for generating gears which have Slice tooth. Some non-metallic supplies for example compressed paper, rawhide, Wooden and nylon can be utilized to cut back sound in these gears.

Obtaining these bins

There are several production companies from where by one particular can certainly buy these solutions at a discounted level. These production firms have their particular manufacturing device equipped with latest applications. They may have specialized groups to glance after the creation of these items. One can immediately purchase these items through the makers or sellers or can browse by means of the net for getting information regarding these solutions. There are numerous on the net portals from wherever a single should buy these items. Customers can easily look through as a result of these Internet websites to find out about distinct solutions and to find out about the prices connected with these goods. When getting these containers just one need to generally Examine the effectiveness, reduction ratio, highest tooth contact and specific tolerance of this stuff.

Upkeep

Many of these packing containers are effortless to keep up. These ought to be frequently cleaned with appropriate cleaning agent. These should be lubricated at normal interval so they function easily and there is hardly any sounds all through their Procedure. Proper lubrication also lowers friction in between the parts of the equipment and improves their longevity.

A Trip Back In Time: How People Talked About Gear Technology Near Me 20 Years Ago

Gears are an integral ingredient of most mechanical gadgets that happen to be in use right now. Gears have huge ranging functions, but they are utilized for transmitting movement in between two shafts. In addition, they offer torque to a tool that a fast spinning compact motor can't provide. A different important aspect of gears is that they give way to the whole process of rotation. This text presents information regarding just most of these gears, particularly reverse gears.

A pair of gears, one particular existing about the counter shaft and the other around the output shaft are utilized to put into action the entire process of 'reverse'. In contrast to forward gears that happen to be meshed jointly, There is certainly some quantity of space in between the reverse gears. A different issue of differentiation from ahead gears is the fact that reverse gears are joined to their shafts. There isn't any free rotation throughout the shaft. There may possibly produce a scenario when a small equipment that is recognized as the reverse idler is slid in between the two gears. The purpose of the gear also referred to as the idler equipment is usually to mesh The 2 gears jointly. This permits it to alter the route in the rotation, but it does not hamper the gear ration in almost any way.

The strategy of Performing of reverse gears is just not as complex as It appears. In the event the reverse gear is selected, the gear tooth of such gears are meshed. There is totally no assist with the mechanism that seeks to synchronize these gears. This is probably the Main main reasons why the output shaft should now shift, after a reverse is chosen. That signify an automobile should be stopped when you want to select the reverse equipment. Several cars Use a mechanism wherein the enter shaft also stops spinning when reverse gears are chosen. This decreases the grinding that accompanies the selection of reverse when There is certainly an inertial spinning in the enter shaft.

Auto corporations tend not to essentially takes advantage of a similar reverse systems throughout all would make. Sophisticated technologies make feasible the usage of advanced reverse gears in modern day vehicles. Naturally, these cars come with a significant value tag. But, as a rule a mechanism is made use of https://emiliombaa675.tumblr.com/post/190917267904/what-the-oxford-english-dictionary-doesnt-tell which end the transmission of your enter shaft. If this is not done the automobile makes a whining sound. This is often why all automobile suppliers use the idler that, as aforementioned, can be inserted between The 2 gears. This treatment minimizes the accompanying sound to an excellent extent and while in the services guide of many providers; you can find a mention of This method like a "noise reduction program".

A brand new form of reverse technological innovation has entered the industry inside the the latest situations, identified as 'spur reverse technological know-how'. This engineering has designed a few improvements towards the a single that have been outlined earlier mentioned. But, it's compromised on a number of factors like, robustness, engagements, and noise. Nevertheless it has located acceptability due to the fact there is proscribed driving that can take place in reverse.

30 Of The Punniest Puns You Can Find

An inside equipment hub is a contemporary gearing technological know-how exactly where the equipment is totally enclosed throughout the rear hub of your bicycle. Compared to derailleur techniques or bikes with external sprockets and various totally exposed areas, this a lot more Sophisticated style of bike has all its gears in one compact ingredient Within the rear hub. Buyers of the bike assert that it would make equipment shifting smoother and aids them improve velocity simpler.

The hub gear is costlier in comparison to the exterior type Utilized in most bicycles. Also, it is more intricate, specially when talking about mend. Should you be just a standard bicycle rider, you might not have the ability to make instantaneous fixes right here and there In the event your bicycle has an inner gear hub. You could have to acquire it to an expert repairman.

This modern bicycle equipment, nevertheless, will not demand a lot of meticulous servicing. It is safeguarded via the hub which is life span lubricated. Bikes with this kind of equipment will carry on managing at its peak for a long period In spite of various climatic conditions. They'll final longer compared to chain bicycle kinds, which Typically want typical repairing and replacement of components like sprockets and chain rings, among the Other folks. All they have to have is some regular cleansing and treatment. Hub gears are sealed from water, Filth, and also other equivalent problems.

When it was described that those who are not authorities in bicycles might need a tough time repairing hub gears, a motorcycle using this type of component is less complicated to work because it does not have overlapping gear ratios and operates on a single shifter. You obtain a very good equipment variety without having Substantially equipment modifications, so you can make velocity transitions a lot quicker and smoother.

Hub equipment methods Permit the rider change gears whilst pedaling and coasting. Modifying gears isn't also an issue regardless if the rear wheel is just not relocating. Moreover, colliding Together with the spokes can be a problem for many bicycles, but for those with hub gears, it isn't. For those who bicycle round the city or anywhere you can find frequent stops, this is a very welcoming element. Those who are also biking on tough terrain would locate this handy.

Bicycles with internal gear hub technological know-how are perfect for every day and mountain biking. The features pointed out here are just a few of its attributes http://lanelqje300.fotosdefrases.com/11-ways-to-completely-sabotage-your-understanding-gear-technology that everyone would find advantageous. Whilst bikes with hub gears might be costlier than other forms, they do make Driving a lot easier and safer.